HLC Industries has been supplying lining and pocket material for the men’s garment and textile industry since its founding in 1916. With more than a century of experience, we can deliver quality fabrics to customers in the US and worldwide. We continuously strive to improve our quality and service to ensure we provide products that meet or exceed your expectations and requirements.

During World War II, HLC Industries provided uniform materials to the US Military and continue to serve military and commercial applications with our NIR-compliant fabrics. In this blog, we’ll explore the importance of NIR compliance as well as how to make NIR-compliant fabrics.

What Is NIR Compliance?

Fabrics with NIR compliance are specialized textiles used in manufacturing military uniforms. NIR-compliant fabrics mimic radiation levels surrounding the wearer, making them less visible to infrared sight technology, such as night vision, thermal vision, or thermal imaging. Infrared sight methods are used to spot people in darkness or low-light environments; therefore, NIR-compliant fabrics are crucial in hiding troops from enemies and threats.

Why Is NIR Compliance Important?

NIR-compliant fabric is vital to military personnel in tactical situations due to its detection-avoidance capabilities. Because clothing covers most of the body, it plays an essential role in detection avoidance. Not only does NIR-compliant military clothing protect against environmental conditions such as wind, sun, and rain, but it also serves as a foundation upon which a camouflage pattern can be applied. By implementing NIR-compliant fabric into traditional military uniforms, you can adapt them to enhance their concealment and protection abilities.

How Clothing Is Made NIR Compliant

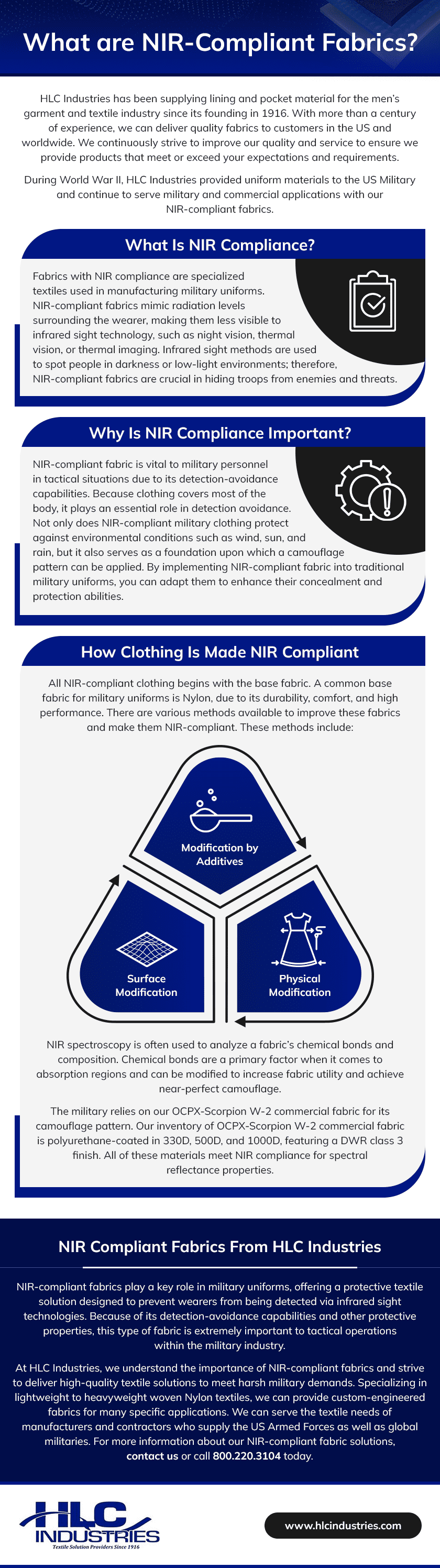

All NIR-compliant clothing begins with the base fabric. A common base fabric for military uniforms is Nylon, due to its durability, comfort, and high performance. There are various methods available to improve these fabrics and make them NIR-compliant. These methods include:

- Modification by additives

- Physical modification

- Surface modification

NIR spectroscopy is often used to analyze a fabric’s chemical bonds and composition. Chemical bonds are a primary factor when it comes to absorption regions and can be modified to increase fabric utility and achieve near-perfect camouflage.

The military relies on our OCPX-Scorpion W-2 commercial fabric for its camouflage pattern. Our inventory of OCPX-Scorpion W-2 commercial fabric is polyurethane-coated in 330D, 500D, and 1000D, featuring a DWR class 3 finish. All of these materials meet NIR compliance for spectral reflectance properties.

NIR Compliant Fabrics From HLC Industries

NIR-compliant fabrics play a key role in military uniforms, offering a protective textile solution designed to prevent wearers from being detected via infrared sight technologies. Because of its detection-avoidance capabilities and other protective properties, this type of fabric is extremely important to tactical operations within the military industry.

At HLC Industries, we understand the importance of NIR-compliant fabrics and strive to deliver high-quality textile solutions to meet harsh military demands. Specializing in lightweight to heavyweight woven Nylon textiles, we can provide custom-engineered fabrics for many specific applications. We can serve the textile needs of manufacturers and contractors who supply the US Armed Forces as well as global militaries. For more information about our NIR-compliant fabric solutions, contact us or call 800.220.3104 today.